Introduction to Wiring Harnesses

Wiring Harness Basics

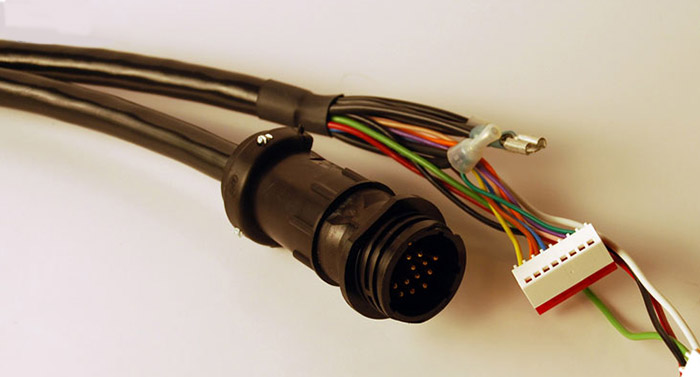

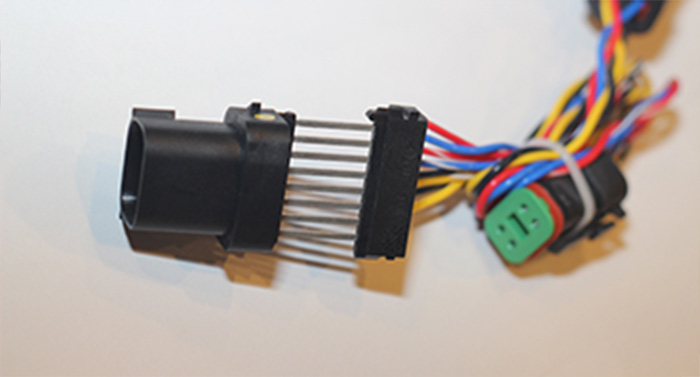

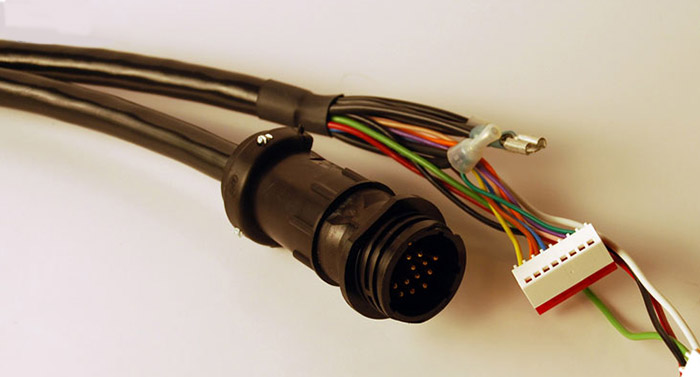

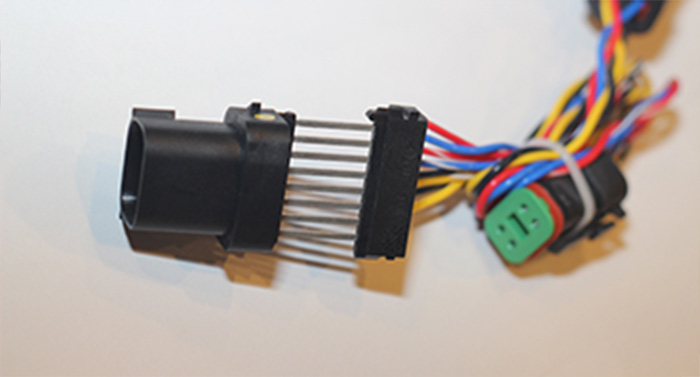

A wire harness or cable assembly is an assembly of wires or cables that transmits signals or electrical power.

- The wire or cable is frequently bound together with wire ties, lacing, sleeves, tape conduit or a number of other options including a combination of the above.

- A harness provides advantages over loose wires and cables by offering decreased installation time and allows for standardization.

- Wires often have terminals attached which can then be assembled into keyed housings for error proofing and connection to other parts of the final assembly.

- Harness assembly is typically done manually due to the many different processes involved.

- Refer to Ever First wiring harness design guidelines for more information.

Wiring harness design is often overlooked in the product development.

- This can result in incomplete drawings and obstacles in the manufacturing process.

- Early partnership with Ever First can help guide the design by avoiding many last minute changes.

- OEM Tooling and material lead times can be very long – advanced planning is important.

Harnessing can be broken down into several areas:

- Leaded wire

- Frequently used in point to point wiring

- Typically made on automated equipment

- Low complexity

- Minimal labor

- Good quality

- Additional savings opportunities for customer with bundling the leads into a harness

Wiring Harness or Cable Assembly

- Usually includes terminals and housings along with other components

- This can be made via a mix of manual and automated operations

- Often this has a higher labor content and need for the higher quality controls developed by Ever First which includes 100% testing

- Wiring Harnesses are made up of individual wires where as Cable Assemblies are made with a multi conductor jacketed cable

Cutting/ Stripping/ Crimping

- A key aspect of a high quality harness is the terminal crimp

- Crimping is a method of attaching a terminal or contact end to an electrical conductor

- Essential to control for maintaining good electrical and mechanical characteristics

- Use of OEM components and tooling contribute to a high quality consistent connection

- Ever First goes well beyond simply checking crimp height, width and pull test by use of a full terminal verification which includes a cross section analysis of the crim

|